Vancity was founded in 1946 to be a different, values-based financial institution. Today, it manages over $35.5 billion in assets and serves 570,000 member-owners across Metro Vancouver, the Fraser Valley, Victoria, Squamish, and Alert Bay—on the traditional territories of the Coast Salish and Kwakwaka’wakw peoples. In line with its climate strategy and alignment with the Paris Agreement and the United Nations Sustainable Development Goals, Vancity is working toward achieving net-zero emissions from its facilities, fleet, and refrigerant use (Scope 1 and 2) by 2040. Scope 1 emissions include heating its buildings, fuel used by its small fleet of service vehicles, and refrigerant use. Scope 2 emissions include electricity used in its operations.

Vancity operates more than 50 branches and offices, primarily leased spaces located in British Columbia, with a single location in Ontario. More than half of these facilities rely on gas for space heating, and most locations use electricity for domestic hot water. Vancity actively monitors the energy use in these facilities, optimizes controls to reduce energy consumption, and has installed LED lighting in nearly all locations.

Despite these efforts, reducing emissions in leased buildings presents added complexity, particularly when it comes to retrofits. Building envelope upgrades are often unfeasible in leased spaces, making deep emissions reductions difficult to achieve through efficiency measures alone. Therefore, to achieve net-zero emissions from its operations, Vancity will need to make significant reductions in GHG emissions—reductions that hinge on fuel-switching. To meet this goal, Vancity’s strategy focuses on the following key actions:

-

Creating a working group focused on real estate decarbonization, bringing together facilities management and sustainable operations teams;

-

Switching the energy sources of its branches and offices from fossil gas to renewable electricity from BC Hydro’s grid;

-

Electrifying its fleet of service vehicles;

-

Using refrigerants with lower global warming potential.

Putting it into Practice

In 2024, Vancity developed a phased plan to replace gas-powered heating, ventilation, and cooling (HVAC) systems with electric heat pumps across its branch network. The process begins by identifying branches with rooftop units (RTUs) that have reached the end of their useful life. Vancity then works with its real estate team to prioritize locations with longer lease terms and ensures that selected branches have adequate feedback systems to support the new equipment. Vancity has also made direct digital controls (DDC) a requirement for heat pump installations, enabling proper monitoring and control of the new heat pump HVAC systems.

The first RTU conversion took place at Vancity’s Guildford branch in Surrey, where five RTUs were replaced in March 2024, resulting in a full conversion from gas to electricity at the branch. One year after eliminating fossil gas use, the branch has already delivered measurable results:

-

Minimal utility cost increase - Total annual utility costs increased by a minimal 4% compared to the previous year, using gas and electricity to power the branch. Vancity also observed lower utility costs during the shoulder and cooling seasons (April – October), and higher costs during the heating season (November – March).

-

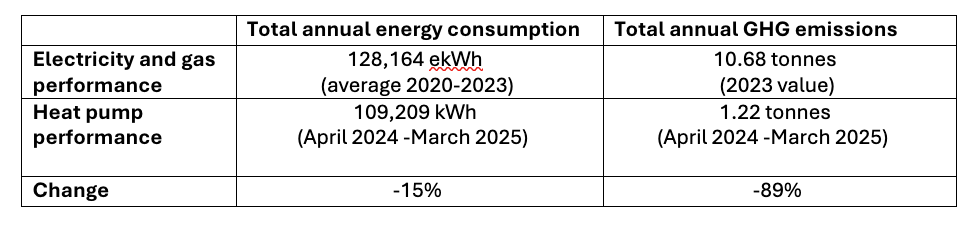

Improved energy efficiency and reduced GHG emissions – Post-installation electricity consumption was 15% lower than the average combined gas and electricity consumption from the past 4 years. GHG emissions decreased by 89% per year.

Key Learnings

By June 2025, Vancity had completed four branch conversions from gas RTUs to electric heat pumps, gaining valuable insights along the way. The insights gained through this process are outlined below to inform other electrification efforts.

1. Laying the groundwork

-

Align your asset replacement strategy with your climate strategy. Aligning asset replacement with climate strategy should involve considering equipment lifespan, performance, lease renewal timelines, and location strategy during prioritization. For portfolio-wide decarbonization, replacing HVAC units at the end of their service life proved to be the most cost-effective moment to transition to electric heat pumps. The cost of the heat pumps themselves was comparable to equivalent gas units, with minimal price difference. The cost premium came from engineering work, electrical upgrades, and the installation of new monitoring technologies.

-

Prepare for worst-case scenarios. Vancity requires fully redundant back-up systems to minimize the potential burden on the maintenance team. Note that this will increase the electrical load for extreme weather events in the winter.

-

Clarify ownership and cost responsibility. Confirm whether HVAC systems fall under the responsibility of the organization or the landlord. If the organization is responsible, it will bear the full replacement cost. If the systems are landlord-owned, there may be opportunities to cost-share—for example, by covering the difference between a standard replacement and a heat pump upgrade.

-

Engage the right partners and conduct the necessary assessments early in the planning process. Successful fuel-switching projects typically require collaboration between an electrical engineer, an electrician, and an equipment supplier. The electrical engineer should assess whether the building’s existing electrical infrastructure can support the additional load. The electrician can identify any upgrades required to enable installation. The equipment supplier can recommend heat pump systems that align with the building’s technical specifications and operational needs.

2. Equipment Selection

-

Verify equipment records. Verify that existing HVAC equipment details—such as name, make, and model—are consistent with landlord documentation and drawing/system names.

-

Check if the new equipment will change the air flow. When replacing HVAC equipment, engage an air balancer to verify that the specified system can deliver the required air volumes for the space. This simple step can prevent performance issues and ensure compliance with code updates.

-

Future-proof your purchase. The newly available R-454b refrigerant has a significantly lower global warming potential (GWP) than R-410a, which is still commonly used in most commercial HVAC systems. Confirm with the mechanical designer and equipment supplier that the system you select has the lowest GWP possible.

-

Consider investing in modulating dampers or economizers to help with energy efficiency. Modulating dampers or economizers can improve energy efficiency by reducing unnecessary ventilation. Selecting HVAC models with this feature and compatible control systems allows dampers to close when fresh air isn’t needed—such as during pre-heating or pre-cooling before occupancy. Note that this is more cost-effective to include before installation rather than after installation.

3. Implementation and Performance Management

-

Coordinate site visits. Have the electrical engineer and electrician visit the site together to review upgrade plans in person. On-site conditions can reveal issues that drawings and photos might miss.

-

Inspect the breaker panels, particularly the circuits that will be used for the new heat pumps. Older breakers are susceptible to failure and may need to be replaced, so it is important to account for this in the project budget.

-

Consider investing in equipment management technology. Direct digital controls (DDC) can provide the precision and remote access needed to operate modern HVAC systems efficiently.

-

Monitor the new setup and tweak accordingly. After installing heat pumps, Vancity tracked utility use and occupant comfort, and found that starting the heating slightly earlier improved conditions by the time staff arrived.

Looking ahead: Scaling decarbonization

Vancity remains committed to achieving net zero emissions – both for financed emissions and its scope 1 and 2 emissions. As the organization grows, it continues to prioritize emissions reductions, including seeking fully electrified locations.

To accelerate progress toward its emissions reduction goals, Vancity is exploring emerging technologies and forming strategic partnerships that support deep decarbonization. Additionally, a portfolio-wide effort is underway to modernize building systems and implement preventive asset management—enabling more efficient, responsive oversight of HVAC systems across all properties.

A B2E publication written by Vancity:

Nicole Montgomery, Manager, Sustainable Operations

Franco Tortora, Team Manager, Building Maintenance

b2e@zeic.ca

b2e@zeic.ca