Building electrification occurs when a building is disconnected from the fossil fuel distribution network and some to all building system are switched over to run on electricity. In areas where the electricity grid is clean, like in British Columbia, building electrification results in significant greenhouse gas emissions reductions. Some form of energy efficiency improvements, such as air sealing and adding insulation are often necessary prior to electrification to increase comfort and reduce costs.

Optimized Electrification

Optimized Electrification refers to the electrification of a building while maintaining the existing electrical service connection. A grant from the Alberta Ecotrust Foundation was obtained by Passive House Alberta to investigate equipment to support this. Most existing homes have a 100-amp, 240-volt (24-kW) electrical service connection. This article is based on the work of Redwood Energy in California and their Watt Diet Calculator.

In cases where electrifying exceeds the existing electrical panel board capacity, there are direct costs to a homeowner to install a larger electrical service. If the home is fed by overhead electrical lines and the closest electrical transformer has the spare capacity, the cost to install a new 200-amp electrical panel and associated equipment is often in the $3,000-$7,000 range. If the electrical lines are fed underground and/or the transformer is far away, the upgrade costs can increase to $20,000 or more.

Optimized Electrification is important because the electrical distribution network is limited and may not be able to accommodate additional peak load if too many buildings on a street upgrade to a 200-amp, 240-volt electrical service connection. Optimized Electrification helps to avoid costly upgrades to the electrical distribution network infrastructure, which are passed on to all homeowners in the form of “fixed utility connection fees.”

Additional Loads from Electrification

When a building is fully electrified, several new electrical loads are added to the panel:

-

Space Heating: Increasingly Heat Pumps are used for space heating and space cooling and can be either an air-source or ground-source type. With current cold climate air-source heat pumps (ccASHP) technology, a supplementary space heating source is often needed below -25oC as the ccASHP can no longer meet the heating load requirements. As ground-source heat pumps use the stable temperature of the ground, they do not require supplementary space heating. These loads are in the 3-9 kW range.

-

Domestic Hot Water Heating: The best practice is to use a heat pump for domestic hot water (DHW) heating rather than a standard electric resistance tank. Either a split-type or a hybrid heat pump hot water tank (HPHWT) can be used. These loads are in the 3.6 kW to 7.2 kW range as they have supplementary electric resistance heaters built in. Newer 15-amp, 120-volt HPHWT units are coming to market that only have a 1.5 kW load. In heat pump mode all the units draw under 1kW.

-

EV Charging: Demand for at-home electric vehicle (EV) charging is increasing. Speed and size of charging stations results in loads ranging from a L1 charger at up to 1.3 kW to an L2 charger at up to 9.6 kW.

-

ERV or HRV: To help ensure excellent indoor air quality, an energy recovery ventilator (ERV) or heat recovery ventilator (HRV) should be installed if one is not already present. The load of these devices is generally under 1.5 kW.

Load Share Devices and Smart Electrical Panels

If adding any loads listed above pushes the electrical panel over capacity when calculated as per the Canadian Electrical Code, then Load Share Devices or a Smart Electrical Panel can be used. These devices control the peak load that is drawn from individual circuits and/or the entire electrical panel. In February 2023, Technical Safety BC released a bulletin on how additional loads, such as a hot tub or electrical vehicle supply equipment, can be added to the existing service of a single dwelling unit using demand data. Read the clarification of Rule 8-106 8) in the 2021 BC Electrical Code Regulation here.

There are two main types of Load Share Devices.

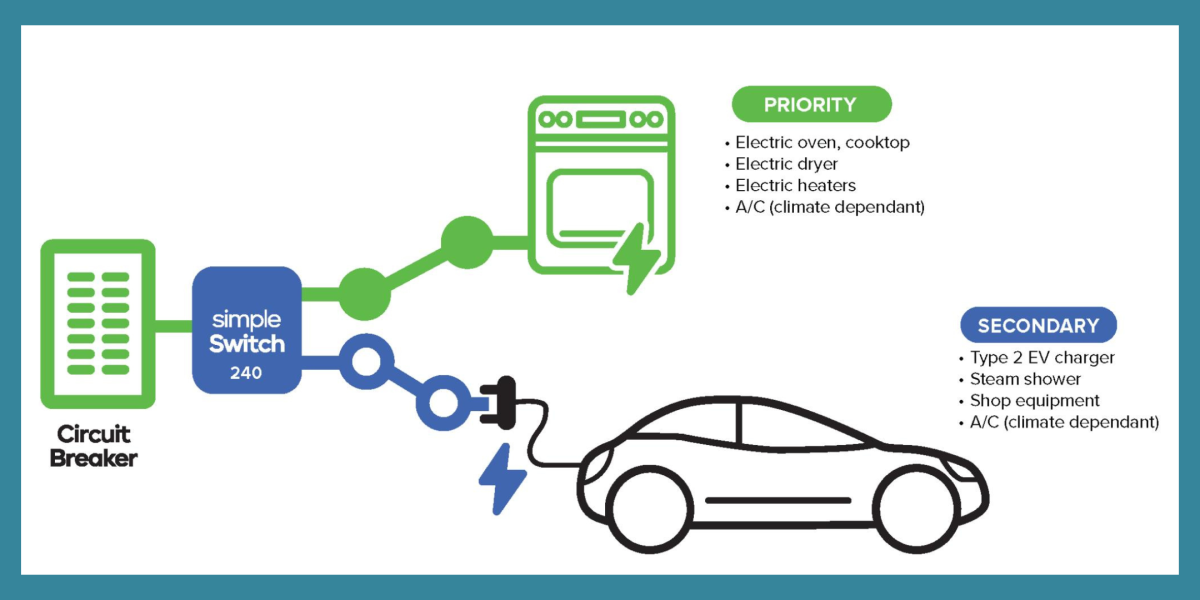

1) Primary and Secondary Load Share Devices

With these Load Share Devices, the appliance connected to the primary side of the load share device always has power. The appliance connected to the secondary side only has power when the primary side is off. Two large loads are thus connected into one circuit breaker, but only the larger one is included in the electrical panel capacity calculation. Equipment costs are between $850 and $1,300.

Image 1: Explanation of a Primary + Secondary Load Share Device, from Simple Switch

Available technology:

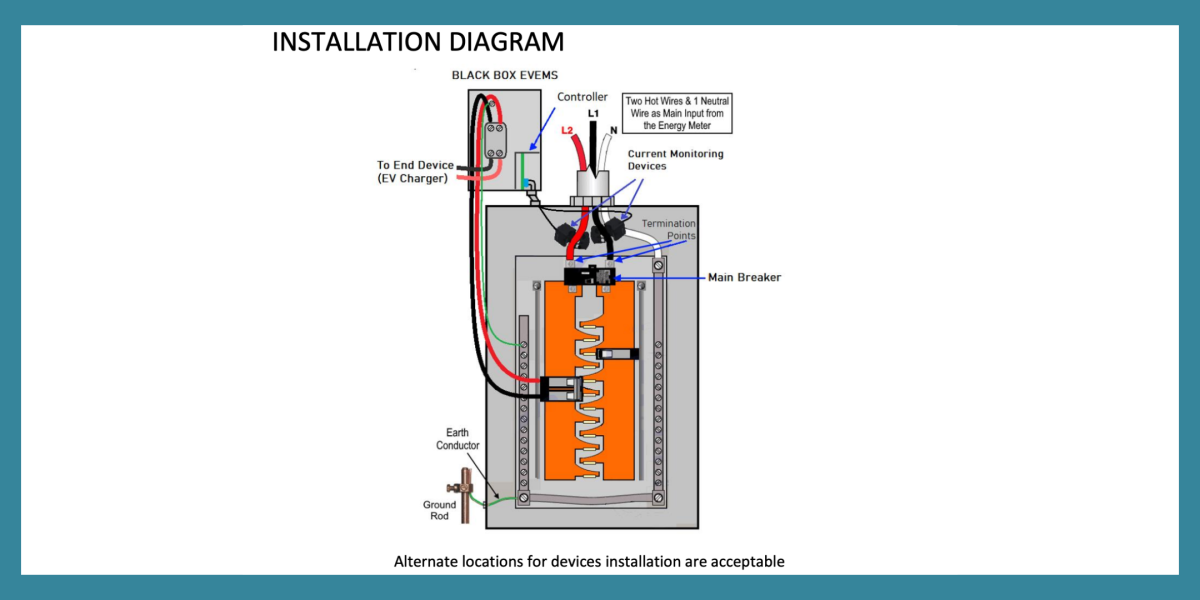

2) Circuit Pauser Load Share Devices

With Circuit Pausers power a connected appliance while monitoring the demand on the main electrical service. If the demand goes over a certain threshold (generally 80% of rated capacity) it will pause the power to the connected appliance until the main electrical service demand drops below the threshold for a set amount of time (generally 15 minutes). The connected load is thus not included in the electrical panel capacity calculation. Equipment costs are between $850 and $1,100.

Image 2: Explanation of a Circuit Pauser from BlackBox Innovations

Available technology:

Smart Electrical Panels

If more than a single appliance or load needs to be connected and controlled, a Smart Electrical Panel can be a better and more economical solution than Load Share Devices. These solutions also work well in new construction, and when more control, prioritizing, monitoring and circuit-by-circuit billing is needed.

Available technology:

-

Koben Genius Smart Electric Panel: Made in Canada, this hybrid solid-state breaker panel can control up to 24 circuits and up to 500 amps. It provides utility grade billing plus circuit-by-circuit control, monitoring and prioritizing. It is a single and three phase panel in one, with the ability to serve as a renewable energy connection. The cost is around $5,000 and can be as low as $3995 for quantity purchases.

-

Lumin Smart Panel: This is an add-on smart electrical panel that can monitor, control, and prioritize up to twelve 120-volt or six 240-volt circuits. It must connect to a standard electrical panel as it has no built-in circuit breakers. The cost is around $3,000.

Tips and Lessons Learned from Load Share Case studies

As part of the grant, load share devices were installed in a small number of homes In Alberta (climate zone 7A). Through this implementation, the project team learned the following:

- An electrician should perform a panel capacity calculation, not all connected loads on the panel count as it is assumed not all will be on at the same time. The Electrical Service Load Calculator for Single Dwellings in Canada can be used as an estimate.

- A certified electrician and electrical permit are required.

- Permitting of load share devices was not an obstacle as the equipment have the required certifications and are installed as per the manufactures intended uses and instructions.

- The installation cost for the load share devices varied from $400 to $700.

- Be aware of the electrical consumption rating on any heat pump clothes dryer. Some models include an electric resistance heater element in the unit, requiring a 30-amp 240-volt connection, despite using much less power in heat pump mode.

- In homes with a secondary suite, the second electric range makes optimized electrification difficult. Consider a 2-burner induction cooktop plus a plug-in countertop convection oven instead.

- Most load share devices have a current transformer or electromagnet in them, so extra care should be taken during the installation to ensure no metal fragments are left in the devices, especially when the “knock out” panels are removed from the electrical boxes. Otherwise, the devices could hum. Vacuuming (not blowing) out the devices is recommended, before energizing.

Generic Pathway for home electrification without a service upgrade:

Step 1: Reduce or reallocate existing loads:

- Improving building envelope to reduce heating load so that a 30-40A HP can fit on the circuit.

- Replace the standalone electric resistance dryer with a condensing dryer or all-in-one washer and condensing dryer combo unit to free up some of the panel board capacity of the 30-amp 240-volt circuit.

- An all-in-one washer and condensing dryer reduce the load on the panel to only one 15-amp 120-volt circuit, with a price comparable to a high-end washer. A separate washer and condensing dryer needs two 15-amp 120-volt circuits.

- The added ERV or HRV reuses the removed fossil-fuel furnace circuit.

- Install an induction range to replace the fossil-fuel cooktop instead of a separate electric cook top and a wall oven as it has internal load controls and thus only needs one large amperage (40-amp 240-volt) circuit.

Step 2: Add new loads and load share as needed:

- The ccASHP often can reuse the electric dryer circuit.

- Some ccASHP brands that use an air handler type indoor unit to replace the removed furnace come with an integrated supplementary electric space heater and internal controls that control the peak electrical load to the larger of the two.

- For other brands or types of ccASHPs, load share the induction range as the primary appliance with the supplementary electric space heater as the secondary appliance.

- Use a Circuit Pauser to add an EV charger or other large load

- For a HPHWT try to use the 15-amp 240-volt models. These lower amperage models are less common, so order early. Buy a larger tank so that it stays in heat pump mode most or all the time. This will not reduce the circuit breaker size but will reduce the energy used.

- If additional large loads need to be added such as workshop equipment, then a smart electrical panel may be required.

For individual and societal benefit, electrification without a service upgrade is an important and cost effectively attainable goal.

Additional details on the case studies can be found at:

- Electrification without Demolition,

- Deep Energy Retrofits and Electrification,

- Panelized and other types of Deep Energy Retrofits

A B2E publication written by Frank Crawford

b2e@zeic.ca

b2e@zeic.ca